No part of this publication may be reproduced, or transmitted, or stored, in any form or

by any means, electronic, mechanical, photocopying, recording, or otherwise, without

the prior written permission of SheetMetalWorkBook.com

Sixth Edition Reformatted for Internet

©2012 SheetMetalWorkBook.com

90 Degree Bends

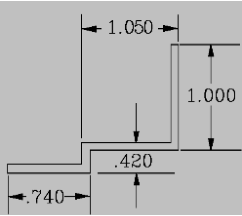

When developing flat length for 90 degree bends always make sure the dimensions are outside

bends always make sure the dimensions are outside to outside. Using the example to the right let us

to outside. Using the example to the right let us say the material thickness is .050 and the bend

say the material thickness is .050 and the bend radius is .032. Our bend allowance would be:

radius is .032. Our bend allowance would be: (.0078 x .050 + .01743 x .032) x 90 = .085

(.0078 x .050 + .01743 x .032) x 90 = .085 Now we can calculate the bend deduction:

2 x (.050 + .032) = .164

.164 - .085 = .079 B.D.

Look at the two pictures closely and notice

Now we can calculate the bend deduction:

2 x (.050 + .032) = .164

.164 - .085 = .079 B.D.

Look at the two pictures closely and notice the different way each is dimensioned. They are

the different way each is dimensioned. They are both identical parts. The first picture is shown

both identical parts. The first picture is shown dimensioned like a typical blueprint. The second

dimensioned like a typical blueprint. The second is the dimensions we need for our flat pattern

is the dimensions we need for our flat pattern development. We got the bottom dimensions from

development. We got the bottom dimensions from the information on the first drawing.

the information on the first drawing. Note that the .370 dimension is located from

Note that the .370 dimension is located from outside of a bend to the inside of a bend. We

outside of a bend to the inside of a bend. We will have to add a material thickness to the .370

will have to add a material thickness to the .370 dim. making it .420. The 1.050 dim. on the bottom

dim. making it .420. The 1.050 dim. on the bottom picture came from subtracting .740 from 1.740

picture came from subtracting .740 from 1.740 which would give us a distance of 1.000 from

which would give us a distance of 1.000 from outside to inside. Now we have to add a material

outside to inside. Now we have to add a material thickness to the 1.000 dim. making it 1.050 which

thickness to the 1.000 dim. making it 1.050 which now gives us all of our outside dimensions. We

now gives us all of our outside dimensions. We can do our development next.

can do our development next. Below is an easy way of keeping track of our

Below is an easy way of keeping track of our bends and bend deductions. You can count the

bends and bend deductions. You can count the B.D.'s and see that we are figuring for 3 bends.

B.D.'s and see that we are figuring for 3 bends. .740

-.079 B.D.

.661

+.420

1.081

-.079 B.D.

1.002

+1.050

2.052

-.079 B.D.

1.973

+1.000

2.973 = Flat stretch out

.740

-.079 B.D.

.661

+.420

1.081

-.079 B.D.

1.002

+1.050

2.052

-.079 B.D.

1.973

+1.000

2.973 = Flat stretch out

bends always make sure the dimensions are outside

bends always make sure the dimensions are outside to outside. Using the example to the right let us

to outside. Using the example to the right let us say the material thickness is .050 and the bend

say the material thickness is .050 and the bend radius is .032. Our bend allowance would be:

radius is .032. Our bend allowance would be: (.0078 x .050 + .01743 x .032) x 90 = .085

(.0078 x .050 + .01743 x .032) x 90 = .085 Now we can calculate the bend deduction:

2 x (.050 + .032) = .164

.164 - .085 = .079 B.D.

Look at the two pictures closely and notice

Now we can calculate the bend deduction:

2 x (.050 + .032) = .164

.164 - .085 = .079 B.D.

Look at the two pictures closely and notice the different way each is dimensioned. They are

the different way each is dimensioned. They are both identical parts. The first picture is shown

both identical parts. The first picture is shown dimensioned like a typical blueprint. The second

dimensioned like a typical blueprint. The second is the dimensions we need for our flat pattern

is the dimensions we need for our flat pattern development. We got the bottom dimensions from

development. We got the bottom dimensions from the information on the first drawing.

the information on the first drawing. Note that the .370 dimension is located from

Note that the .370 dimension is located from outside of a bend to the inside of a bend. We

outside of a bend to the inside of a bend. We will have to add a material thickness to the .370

will have to add a material thickness to the .370 dim. making it .420. The 1.050 dim. on the bottom

dim. making it .420. The 1.050 dim. on the bottom picture came from subtracting .740 from 1.740

picture came from subtracting .740 from 1.740 which would give us a distance of 1.000 from

which would give us a distance of 1.000 from outside to inside. Now we have to add a material

outside to inside. Now we have to add a material thickness to the 1.000 dim. making it 1.050 which

thickness to the 1.000 dim. making it 1.050 which now gives us all of our outside dimensions. We

now gives us all of our outside dimensions. We can do our development next.

can do our development next. Below is an easy way of keeping track of our

Below is an easy way of keeping track of our bends and bend deductions. You can count the

bends and bend deductions. You can count the B.D.'s and see that we are figuring for 3 bends.

B.D.'s and see that we are figuring for 3 bends. .740

-.079 B.D.

.661

+.420

1.081

-.079 B.D.

1.002

+1.050

2.052

-.079 B.D.

1.973

+1.000

2.973 = Flat stretch out

.740

-.079 B.D.

.661

+.420

1.081

-.079 B.D.

1.002

+1.050

2.052

-.079 B.D.

1.973

+1.000

2.973 = Flat stretch out