No part of this publication may be reproduced, or transmitted, or stored, in any form or

by any means, electronic, mechanical, photocopying, recording, or otherwise, without

the prior written permission of SheetMetalWorkBook.com

Sixth Edition Reformatted for Internet

©2012 SheetMetalWorkBook.com

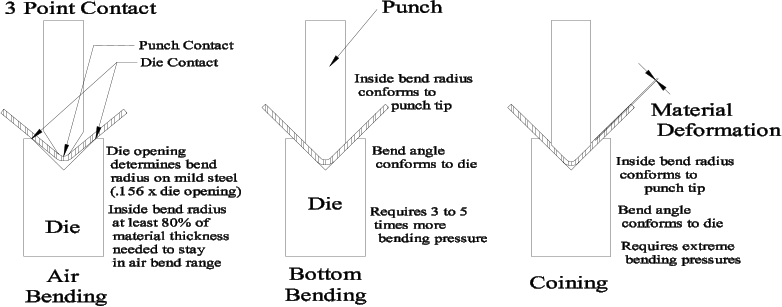

Three terms used for forming sheet metal.

AIR BENDING: 3 point contact of metal. Punch tip and die edges. Air bending is what most bend allowance formulas are based on. When

bending is what most bend allowance formulas are based on. When forming mild steel the inside bend radius is based upon bottom die V

forming mild steel the inside bend radius is based upon bottom die V opening. It is close to 15.6 percent of the die opening. Therefore a

opening. It is close to 15.6 percent of the die opening. Therefore a 3/8 die opening would produce an inside bend radius of .059.

3/8 die opening would produce an inside bend radius of .059. .375 x .156 = .0585 (Almost a 1/16 bend radius)

On most aluminum alloys the inside bend radius would be determined by

.375 x .156 = .0585 (Almost a 1/16 bend radius)

On most aluminum alloys the inside bend radius would be determined by the punch tip radius (i.e. if using a punch tip with .06 radius on

the punch tip radius (i.e. if using a punch tip with .06 radius on .063 5052-H32 aluminum the bend radius will be close to .06).

.063 5052-H32 aluminum the bend radius will be close to .06). To stay in the air bending range the inside bend radius needs to be no

To stay in the air bending range the inside bend radius needs to be no less than about 80 percent of the material thickness. Anything less

less than about 80 percent of the material thickness. Anything less would be considered bottom bending. For example: Let's take that .375

would be considered bottom bending. For example: Let's take that .375 die opening which produces a .0585 bend radius and try to apply it to

die opening which produces a .0585 bend radius and try to apply it to .090 cold roll steel. We take the .0585 and divide it by the material

.090 cold roll steel. We take the .0585 and divide it by the material thickness to see what percentage of the material the radius is.

thickness to see what percentage of the material the radius is. .0585 ÷ 090 = .65

The radius produced is 65 percent of the material thickness, that

.0585 ÷ 090 = .65

The radius produced is 65 percent of the material thickness, that would put us into the bottom bending range. We would have to go to a

would put us into the bottom bending range. We would have to go to a larger V opening for the die. To find out what size V opening you need

larger V opening for the die. To find out what size V opening you need for a 3/32 or .094 Bend radius just take the radius and divide it by

for a 3/32 or .094 Bend radius just take the radius and divide it by 15.6 percent.

15.6 percent. .094 ÷ 156 = .6025

.094 ÷ 156 = .6025 .602 rounding it off to a 5/8th V die would work just fine.

.602 rounding it off to a 5/8th V die would work just fine. BOTTOM BENDING: This is where material is bent to conform to a set of

BOTTOM BENDING: This is where material is bent to conform to a set of dies that are doing the forming. Full surface contact of metal to dies

dies that are doing the forming. Full surface contact of metal to dies will occur. Angles and inside bend radius of formed sheet metal are

will occur. Angles and inside bend radius of formed sheet metal are determined by the punch and die

determined by the punch and die COINING: This is where actual deformation of the material occurs. The

sheet metal that is compressed between the punch and die is actually

thinner than it was originally before the forming operation.

COINING: This is where actual deformation of the material occurs. The

sheet metal that is compressed between the punch and die is actually

thinner than it was originally before the forming operation.

bending is what most bend allowance formulas are based on. When

bending is what most bend allowance formulas are based on. When forming mild steel the inside bend radius is based upon bottom die V

forming mild steel the inside bend radius is based upon bottom die V opening. It is close to 15.6 percent of the die opening. Therefore a

opening. It is close to 15.6 percent of the die opening. Therefore a 3/8 die opening would produce an inside bend radius of .059.

3/8 die opening would produce an inside bend radius of .059. .375 x .156 = .0585 (Almost a 1/16 bend radius)

On most aluminum alloys the inside bend radius would be determined by

.375 x .156 = .0585 (Almost a 1/16 bend radius)

On most aluminum alloys the inside bend radius would be determined by the punch tip radius (i.e. if using a punch tip with .06 radius on

the punch tip radius (i.e. if using a punch tip with .06 radius on .063 5052-H32 aluminum the bend radius will be close to .06).

.063 5052-H32 aluminum the bend radius will be close to .06). To stay in the air bending range the inside bend radius needs to be no

To stay in the air bending range the inside bend radius needs to be no less than about 80 percent of the material thickness. Anything less

less than about 80 percent of the material thickness. Anything less would be considered bottom bending. For example: Let's take that .375

would be considered bottom bending. For example: Let's take that .375 die opening which produces a .0585 bend radius and try to apply it to

die opening which produces a .0585 bend radius and try to apply it to .090 cold roll steel. We take the .0585 and divide it by the material

.090 cold roll steel. We take the .0585 and divide it by the material thickness to see what percentage of the material the radius is.

thickness to see what percentage of the material the radius is. .0585 ÷ 090 = .65

The radius produced is 65 percent of the material thickness, that

.0585 ÷ 090 = .65

The radius produced is 65 percent of the material thickness, that would put us into the bottom bending range. We would have to go to a

would put us into the bottom bending range. We would have to go to a larger V opening for the die. To find out what size V opening you need

larger V opening for the die. To find out what size V opening you need for a 3/32 or .094 Bend radius just take the radius and divide it by

for a 3/32 or .094 Bend radius just take the radius and divide it by 15.6 percent.

15.6 percent. .094 ÷ 156 = .6025

.094 ÷ 156 = .6025 .602 rounding it off to a 5/8th V die would work just fine.

.602 rounding it off to a 5/8th V die would work just fine. BOTTOM BENDING: This is where material is bent to conform to a set of

BOTTOM BENDING: This is where material is bent to conform to a set of dies that are doing the forming. Full surface contact of metal to dies

dies that are doing the forming. Full surface contact of metal to dies will occur. Angles and inside bend radius of formed sheet metal are

will occur. Angles and inside bend radius of formed sheet metal are determined by the punch and die

determined by the punch and die COINING: This is where actual deformation of the material occurs. The

sheet metal that is compressed between the punch and die is actually

thinner than it was originally before the forming operation.

COINING: This is where actual deformation of the material occurs. The

sheet metal that is compressed between the punch and die is actually

thinner than it was originally before the forming operation.

Bending