No part of this publication may be reproduced, or transmitted, or stored, in any form or

by any means, electronic, mechanical, photocopying, recording, or otherwise, without

the prior written permission of SheetMetalWorkBook.com

Sixth Edition Reformatted for Internet

©2012 SheetMetalWorkBook.com

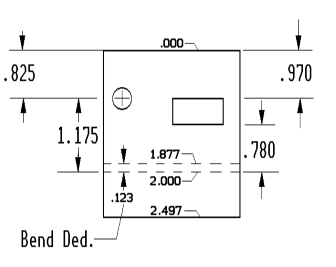

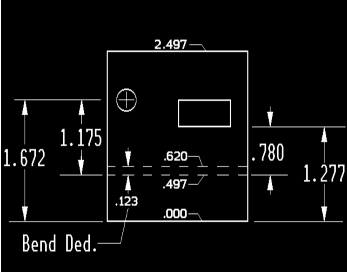

Dimensioning Internal Features

Dimensioning internal features is done the same way as figuring developed lengths or widths. Bend deduction or bend allowance

developed lengths or widths. Bend deduction or bend allowance compensation has to be used when calculating the placement of

compensation has to be used when calculating the placement of internal fea-tures. Holes and cutouts can be dimensioned on

internal fea-tures. Holes and cutouts can be dimensioned on blueprints many different ways. Some of these can be: from outside

blueprints many different ways. Some of these can be: from outside apex of material of a bend, inside apex of material of a bend, or

apex of material of a bend, inside apex of material of a bend, or from an outside edge of the part.

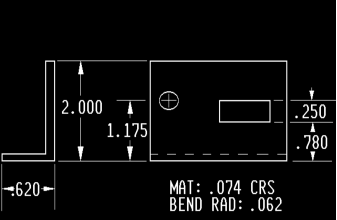

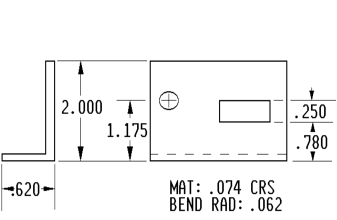

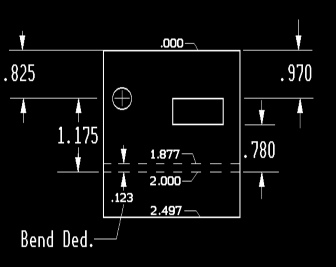

from an outside edge of the part. In the illustrations below the top picture is a representation

In the illustrations below the top picture is a representation of a formed angle as it would possibly appear on a blueprint. The

of a formed angle as it would possibly appear on a blueprint. The hole and cutout is located from the outside apex of the material.

hole and cutout is located from the outside apex of the material. Since this is a ninety degree bend it is also tangent to the bend.

Since this is a ninety degree bend it is also tangent to the bend. to calculate the placement of the hole from the bottom of the

to calculate the placement of the hole from the bottom of the blank you would take .620 minus the bend deduction of .123 and

blank you would take .620 minus the bend deduction of .123 and then add 1.175 giving you 1.672.

then add 1.175 giving you 1.672.

developed lengths or widths. Bend deduction or bend allowance

developed lengths or widths. Bend deduction or bend allowance compensation has to be used when calculating the placement of

compensation has to be used when calculating the placement of internal fea-tures. Holes and cutouts can be dimensioned on

internal fea-tures. Holes and cutouts can be dimensioned on blueprints many different ways. Some of these can be: from outside

blueprints many different ways. Some of these can be: from outside apex of material of a bend, inside apex of material of a bend, or

apex of material of a bend, inside apex of material of a bend, or from an outside edge of the part.

from an outside edge of the part. In the illustrations below the top picture is a representation

In the illustrations below the top picture is a representation of a formed angle as it would possibly appear on a blueprint. The

of a formed angle as it would possibly appear on a blueprint. The hole and cutout is located from the outside apex of the material.

hole and cutout is located from the outside apex of the material. Since this is a ninety degree bend it is also tangent to the bend.

Since this is a ninety degree bend it is also tangent to the bend. to calculate the placement of the hole from the bottom of the

to calculate the placement of the hole from the bottom of the blank you would take .620 minus the bend deduction of .123 and

blank you would take .620 minus the bend deduction of .123 and then add 1.175 giving you 1.672.

then add 1.175 giving you 1.672.

When you get to the acute and obtuse bend sections remember that

obtuse bend sections remember that internal features are calculated

internal features are calculated the same ways that are used for

the same ways that are used for developing overall lengths and

developing overall lengths and widths. Just imagine that the

widths. Just imagine that the dimensions used from the bends to

dimensions used from the bends to the outside edges are going to

the outside edges are going to internal features instead.

internal features instead.

obtuse bend sections remember that

obtuse bend sections remember that internal features are calculated

internal features are calculated the same ways that are used for

the same ways that are used for developing overall lengths and

developing overall lengths and widths. Just imagine that the

widths. Just imagine that the dimensions used from the bends to

dimensions used from the bends to the outside edges are going to

the outside edges are going to internal features instead.

internal features instead.

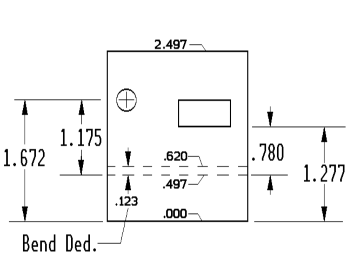

Use .123 Bend Deduction

FLAT PATTERN SAMPLE 2

Dimensions placed from

top of flat part

FLAT PATTERN SAMPLE 1

Dimensions placed from

bottom of flat part