No part of this publication may be reproduced, or transmitted, or stored, in any form or

by any means, electronic, mechanical, photocopying, recording, or otherwise, without

the prior written permission of SheetMetalWorkBook.com

Sixth Edition Reformatted for Internet

©2012 SheetMetalWorkBook.com

Bend Allowance

Bend Deduction, Setback, Bend Allowance, these terms all across the country seem to have no consistent

all across the country seem to have no consistent meaning. They are all used to mean the same thing or

meaning. They are all used to mean the same thing or different things. I will define these terms by what is

different things. I will define these terms by what is usually accepted by most sheet metal mechanics that I

usually accepted by most sheet metal mechanics that I know. These terms may be used differently by your company

know. These terms may be used differently by your company but for the sake of consistency in this manual here are

but for the sake of consistency in this manual here are our definitions. By the way my favorite term so far is

our definitions. By the way my favorite term so far is fudge factor. That seems to be what we are really doing.

fudge factor. That seems to be what we are really doing. BEND ALLOWANCE:

BEND ALLOWANCE: Sheet metal stretches minutely as it is being formed. The

Sheet metal stretches minutely as it is being formed. The greater the inside bend radius is the less the

greater the inside bend radius is the less the stretching. Also material hardness or elasticity has a

stretching. Also material hardness or elasticity has a lot to do with how much it stretches. Therefore bend

lot to do with how much it stretches. Therefore bend allowance is that dimensional adjustment required to

allowance is that dimensional adjustment required to allow for the forming of sheet metal. The mathematical

allow for the forming of sheet metal. The mathematical expression most normally used is based on the empirical

expression most normally used is based on the empirical formula. Empirical means by trial and error. This is how

formula. Empirical means by trial and error. This is how the formula was discovered. They kept adjusting the

the formula was discovered. They kept adjusting the numbers until they found a combination that consistently

numbers until they found a combination that consistently and satisfactorily worked out. Bend allowance and

and satisfactorily worked out. Bend allowance and deduction formulas are used for air bending. Different

deduction formulas are used for air bending. Different results will occur if coining or bottom bending the

results will occur if coining or bottom bending the material.

EMPIRICAL FORMULA:

Bend allowance = (.0078 x MT + .017453 x BR) x A°

MT = Material thickness

BR = bend radius to inside of material

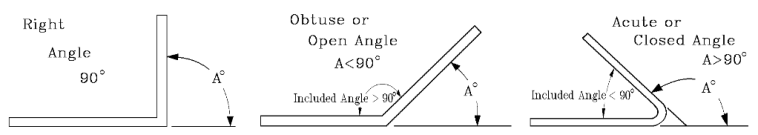

A° = Angle from flat

material.

EMPIRICAL FORMULA:

Bend allowance = (.0078 x MT + .017453 x BR) x A°

MT = Material thickness

BR = bend radius to inside of material

A° = Angle from flat

all across the country seem to have no consistent

all across the country seem to have no consistent meaning. They are all used to mean the same thing or

meaning. They are all used to mean the same thing or different things. I will define these terms by what is

different things. I will define these terms by what is usually accepted by most sheet metal mechanics that I

usually accepted by most sheet metal mechanics that I know. These terms may be used differently by your company

know. These terms may be used differently by your company but for the sake of consistency in this manual here are

but for the sake of consistency in this manual here are our definitions. By the way my favorite term so far is

our definitions. By the way my favorite term so far is fudge factor. That seems to be what we are really doing.

fudge factor. That seems to be what we are really doing. BEND ALLOWANCE:

BEND ALLOWANCE: Sheet metal stretches minutely as it is being formed. The

Sheet metal stretches minutely as it is being formed. The greater the inside bend radius is the less the

greater the inside bend radius is the less the stretching. Also material hardness or elasticity has a

stretching. Also material hardness or elasticity has a lot to do with how much it stretches. Therefore bend

lot to do with how much it stretches. Therefore bend allowance is that dimensional adjustment required to

allowance is that dimensional adjustment required to allow for the forming of sheet metal. The mathematical

allow for the forming of sheet metal. The mathematical expression most normally used is based on the empirical

expression most normally used is based on the empirical formula. Empirical means by trial and error. This is how

formula. Empirical means by trial and error. This is how the formula was discovered. They kept adjusting the

the formula was discovered. They kept adjusting the numbers until they found a combination that consistently

numbers until they found a combination that consistently and satisfactorily worked out. Bend allowance and

and satisfactorily worked out. Bend allowance and deduction formulas are used for air bending. Different

deduction formulas are used for air bending. Different results will occur if coining or bottom bending the

results will occur if coining or bottom bending the material.

EMPIRICAL FORMULA:

Bend allowance = (.0078 x MT + .017453 x BR) x A°

MT = Material thickness

BR = bend radius to inside of material

A° = Angle from flat

material.

EMPIRICAL FORMULA:

Bend allowance = (.0078 x MT + .017453 x BR) x A°

MT = Material thickness

BR = bend radius to inside of material

A° = Angle from flat